The controller box my milling machine originally came with was a bit lack-lustre really. The box itself appeared to be repurposed from a previous life, and from the outside it had minimal indication of what was going on. At some point I added (I can’t remember when) hall effect limit switches and simple opto-isolator based circuit to insulate them from the Gecko stepper driver control board. Later, for reasons I’ll cover in another post, I decided to replace the motor, and that meant building a new control box.

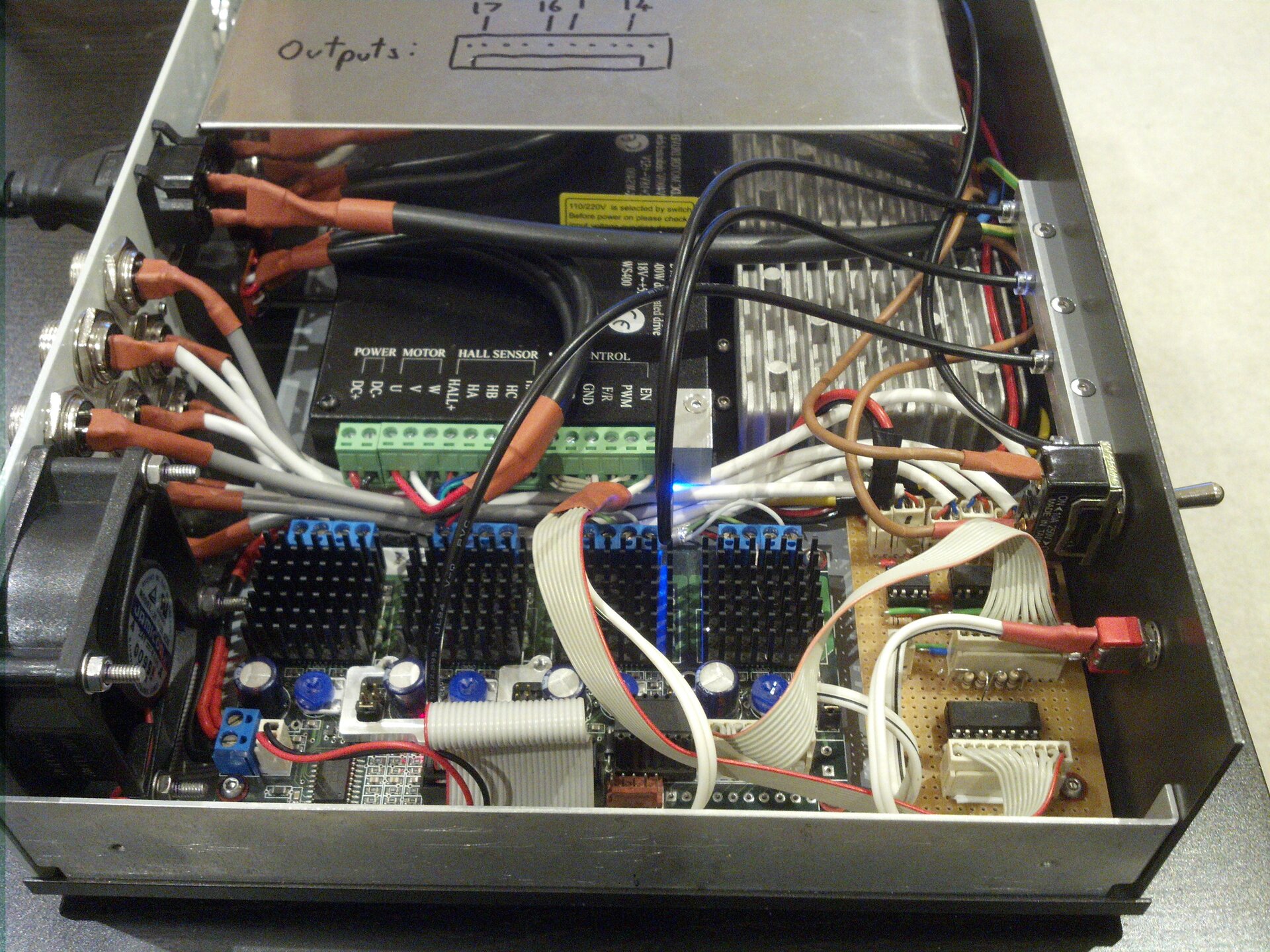

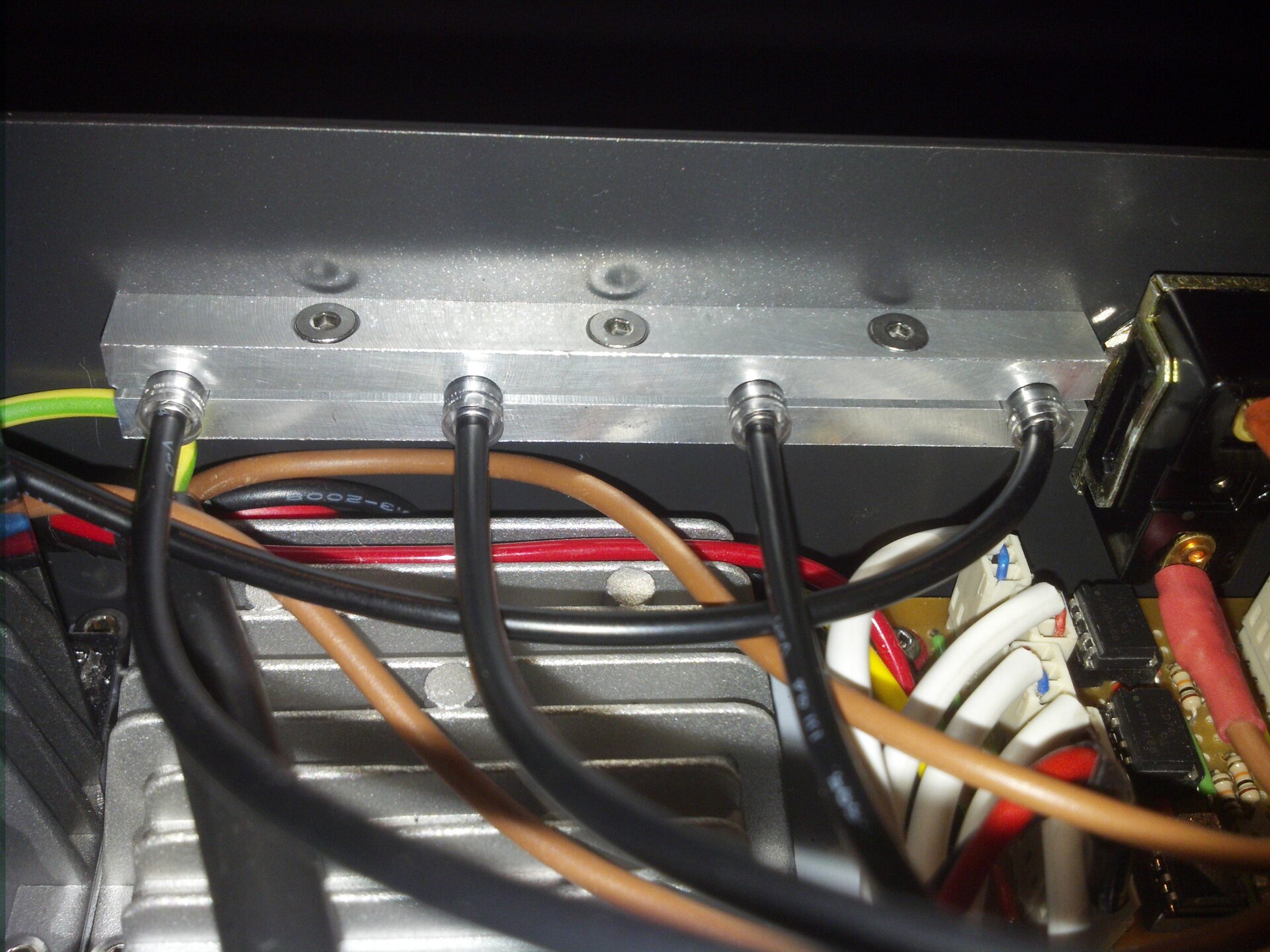

I got a metal off-the-shelf box from somewhere. It needed to house the existing stepper drivers, but also a power supply for said drivers and the new BLDC motor controller. All a bit of a squeeze.

Given I had a CNC machine, it seems rude not to CNC out the front and back panels as required.

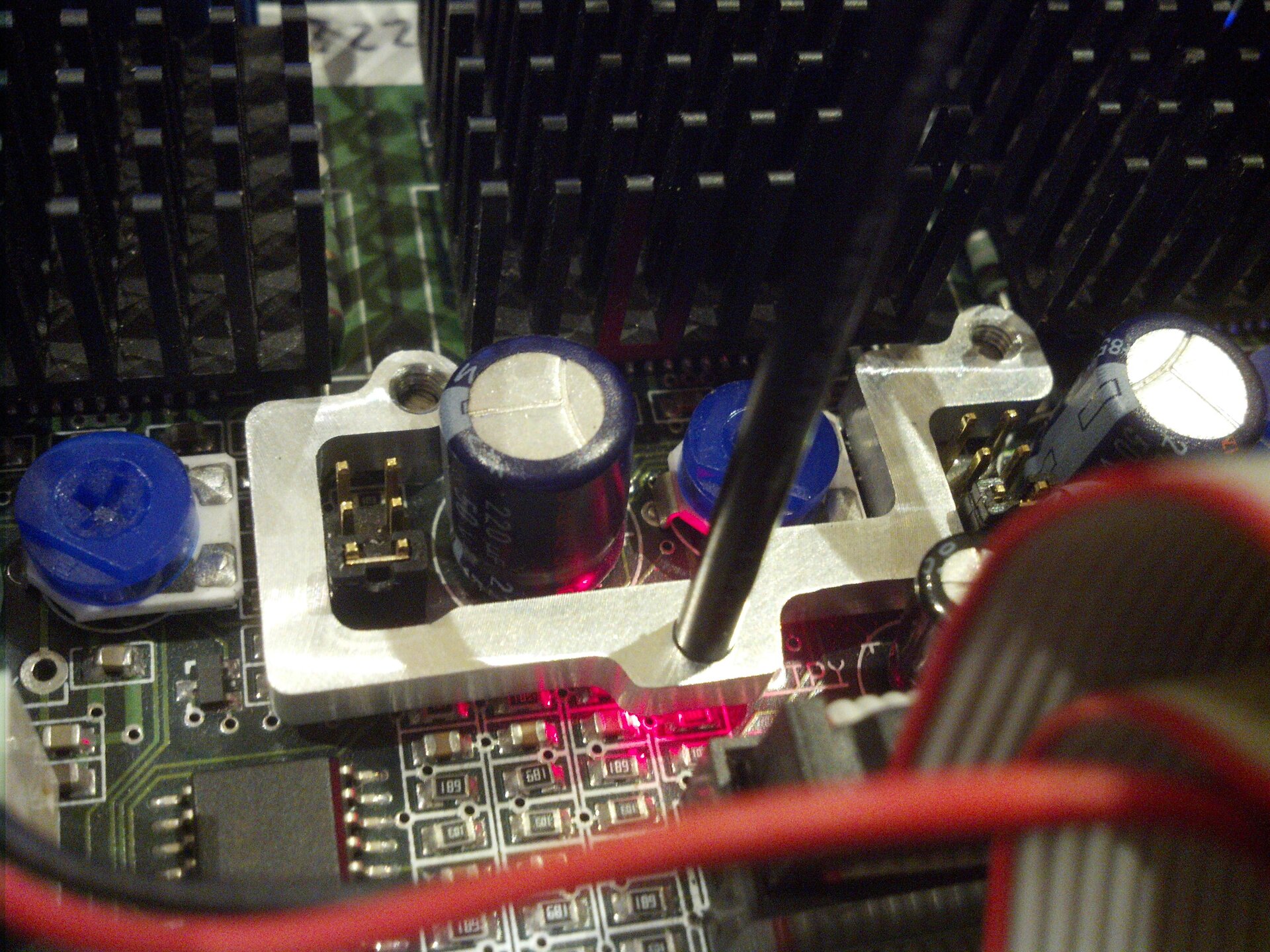

You’ll notice there are several LEDs on the front panel, indicating this or that. I could have tediously desoldered the existing LEDs from their respective boards on the interior and extended them via wires. I had discovered light pipes though, and used those to extend the LEDs optically, rather than electrically.

These days all the brackets would have been much faster to fabricate with a 3D printer, but this predates me getting one. Here’s the box in-situ.

As a bonus, and for lack of a better place for it, here’s a video of the machine going through its homing sequence.