My milling machine originally came with a normal AC motor. This had drawbacks.

Firstly it was manually controlled, both in terms of starting and stopping it, but also adjusting its speed involved moving the belt into one of the positions on its Christmas tree pulleys, hardly ideal. Being a US import, it was also 110V, so I had to run it via a bulky inverter. I vaguely remember investigating if I could rewire it to 230V but presumably this wasn’t possible. To top it off the motor was a bit sluggish to start, although this could be mitigated by giving it a little helping hand. If you forgot though, it had a tendency to blow fuses in the inverter, which as you can imagine gets old really fast.

Therefore I resolved to replace it with something more suitable, preferably speed controllable. I ended up with a Chinese 400W BLDC motor and controller. In hindsight I wish I’d gone with something a bit beefier as the 400W rating is somewhat generous. For 95% of what I do it’s completely fine, but with drilling in particular there is a pucker factor as it can stall when pushed to its limit. Interfacing it with the old Gecko board was straightforward enough, as it produced the requisite PWM signal that the motor controller required. So now I could control the motor activation, speed and direction from the program itself. Great!

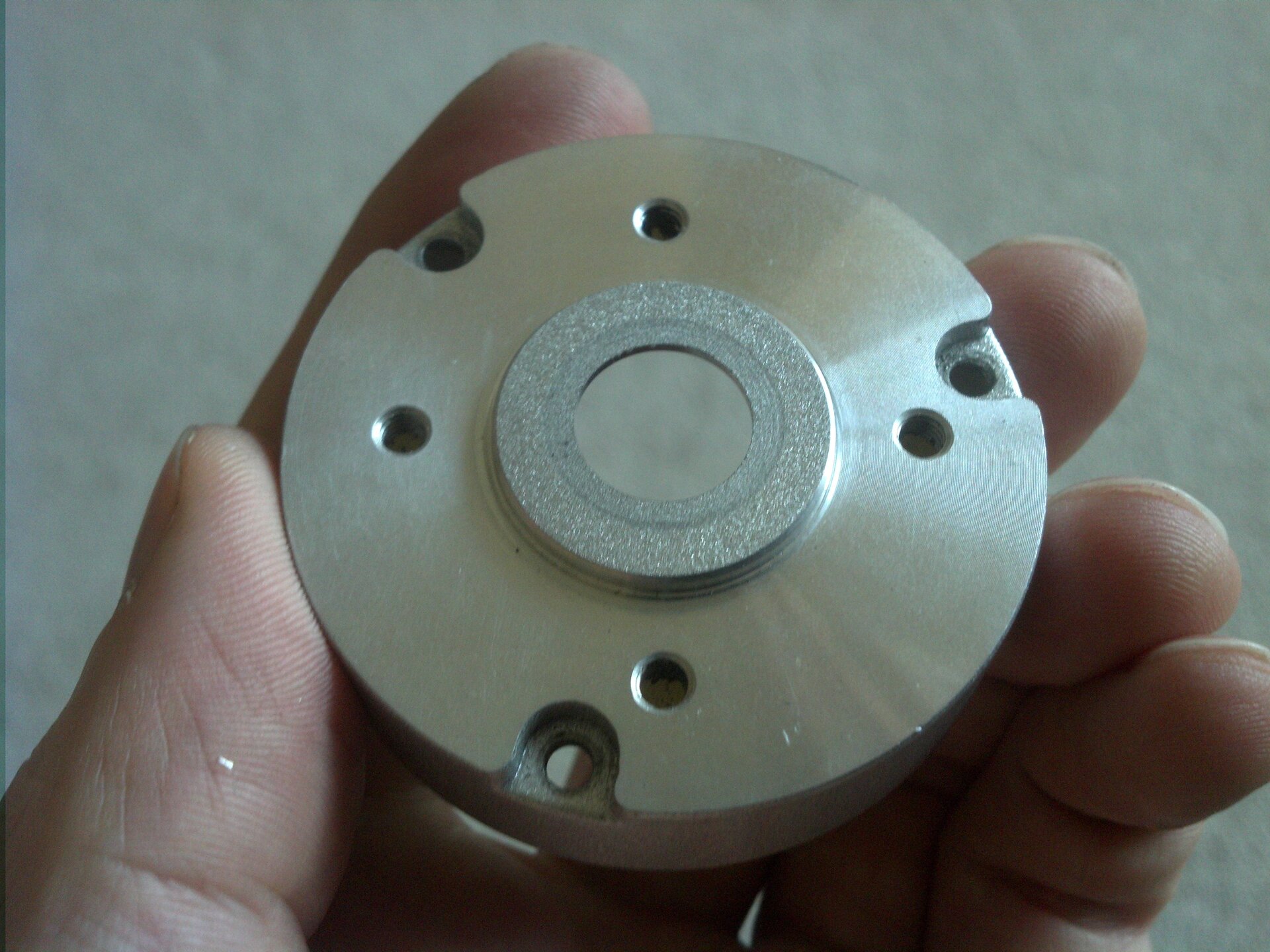

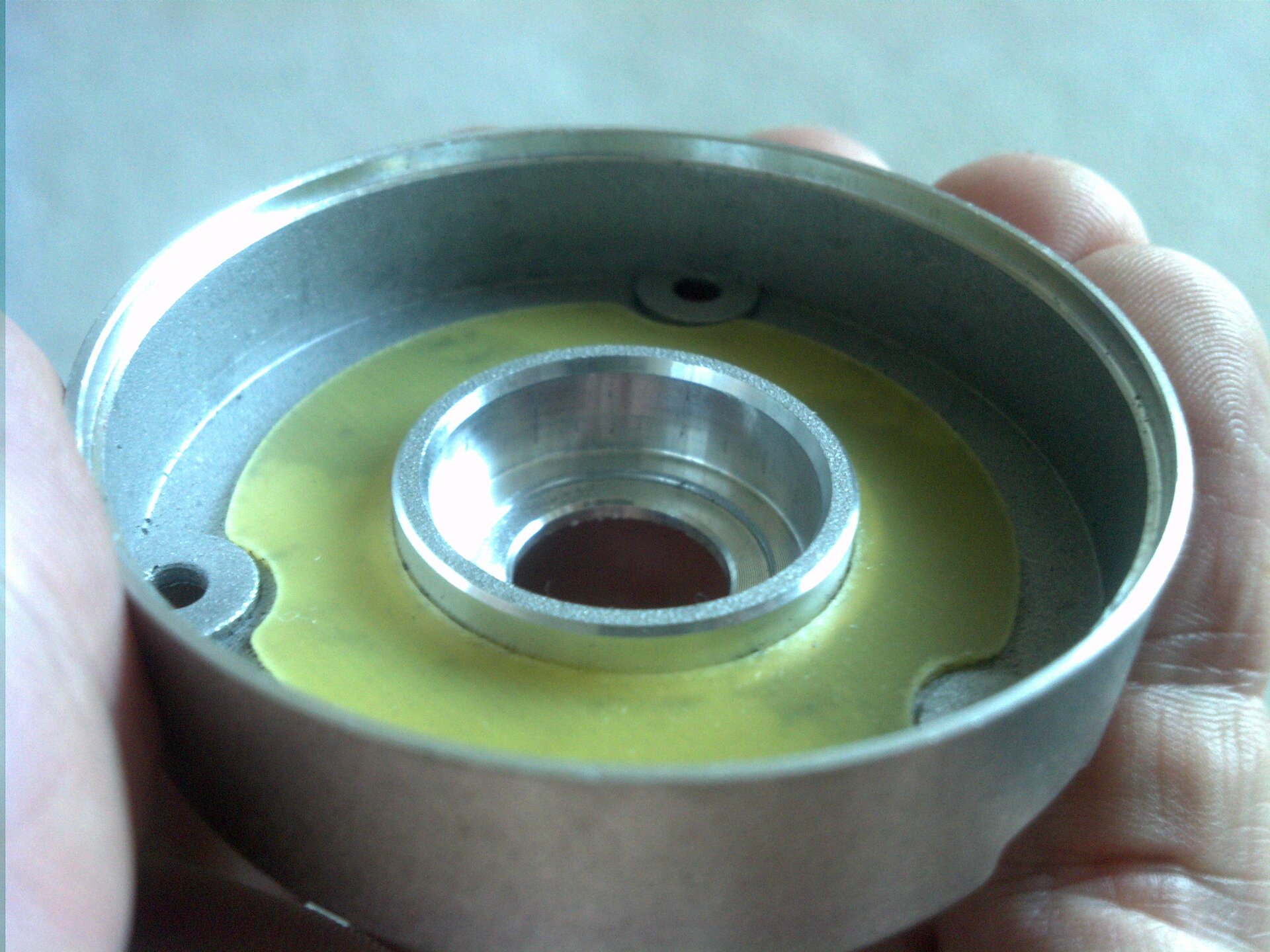

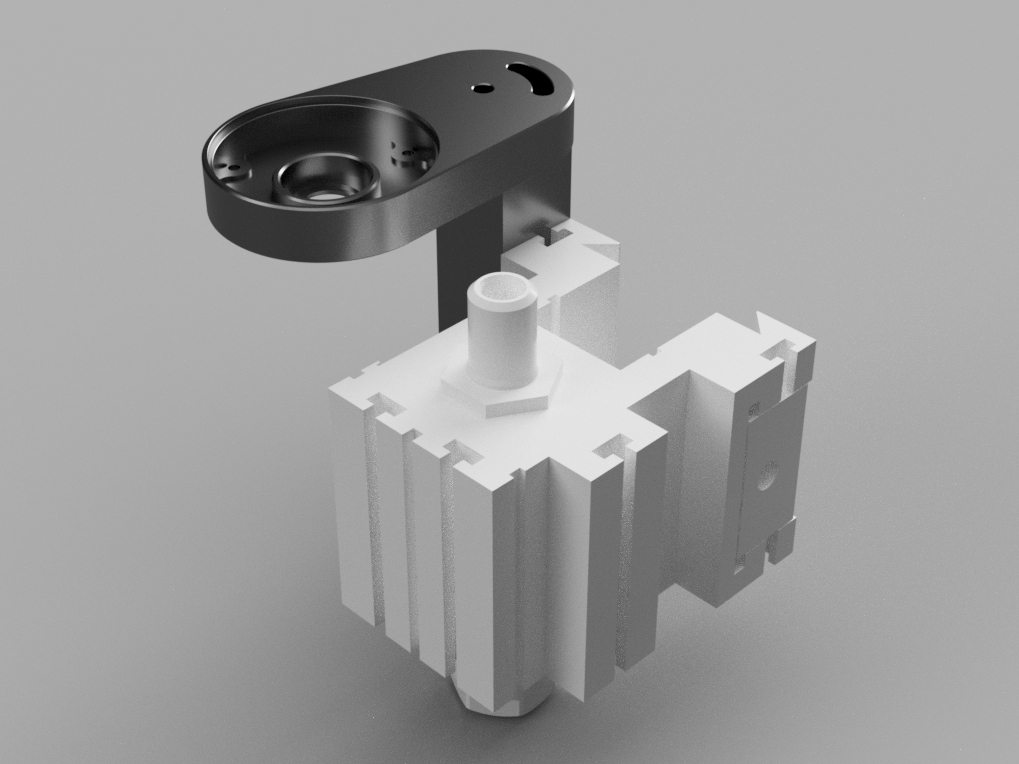

The only thing left was how to mount it. Reading between the lines I think the motor is intended to be direct mounted (I can’t quite remember but I think it came with an ER11 collet system) and run at high RPMs, presumably for engraving and the like. This obviously wasn’t going to work for me though so I had to come up with another scheme. I noticed that the end cap of the motor could be removed easily enough.

The obvious thing to do was to replace it with something that allowed for mounting the motor in place of the original, serving dual purposes of being the end of the motor and a mounting system. Just as well I had a CNC milling machine to make such a thing.

I whipped up a pulley for the motor on my Dad’s lathe and the job’s a good’un.