In another post I mentioned my odd frame requiring an eccentric bottom bracket. I got it into my head that I could modify the frame to take sliding dropouts, a much better solution to the problem.

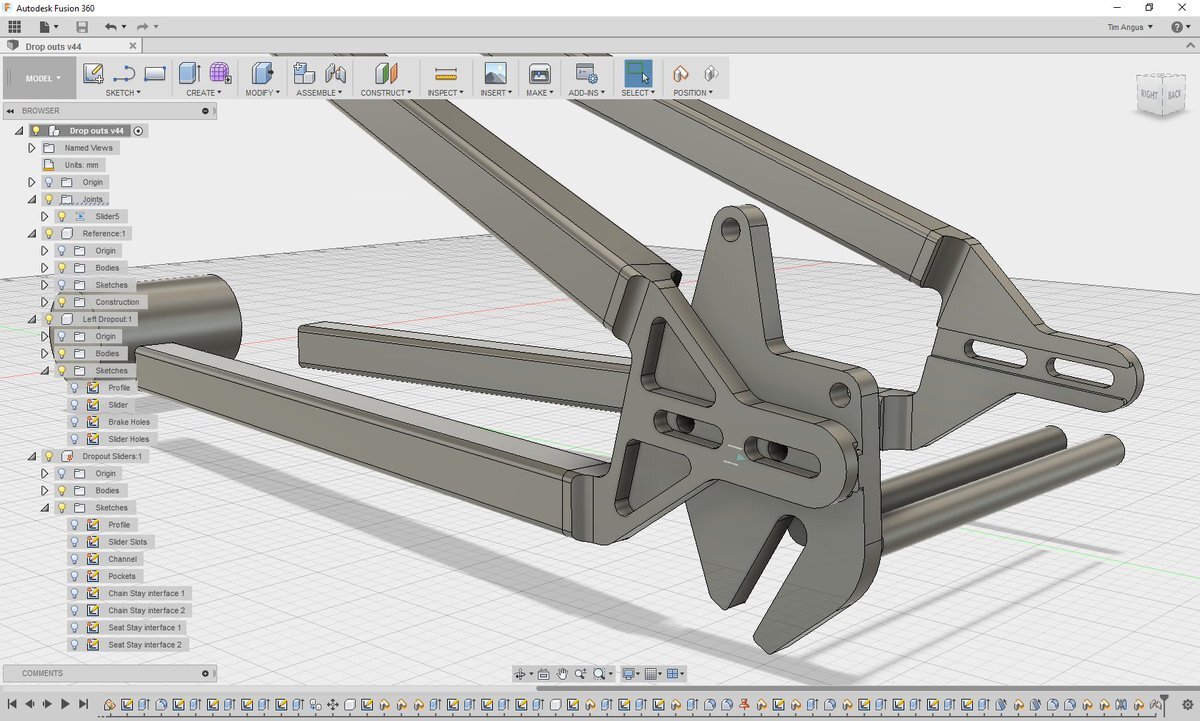

I used it initially as a vehicle for learning Autodesk Fusion over one or other Christmas break. I had a reasonable amount of CAD experience before, but Fusion was new to me.

The idea was that I would get a spare rear end for cheap (which I did), lop the existing dropouts off and weld some new ones CNC machined ones in. Here I am marking where to cut.

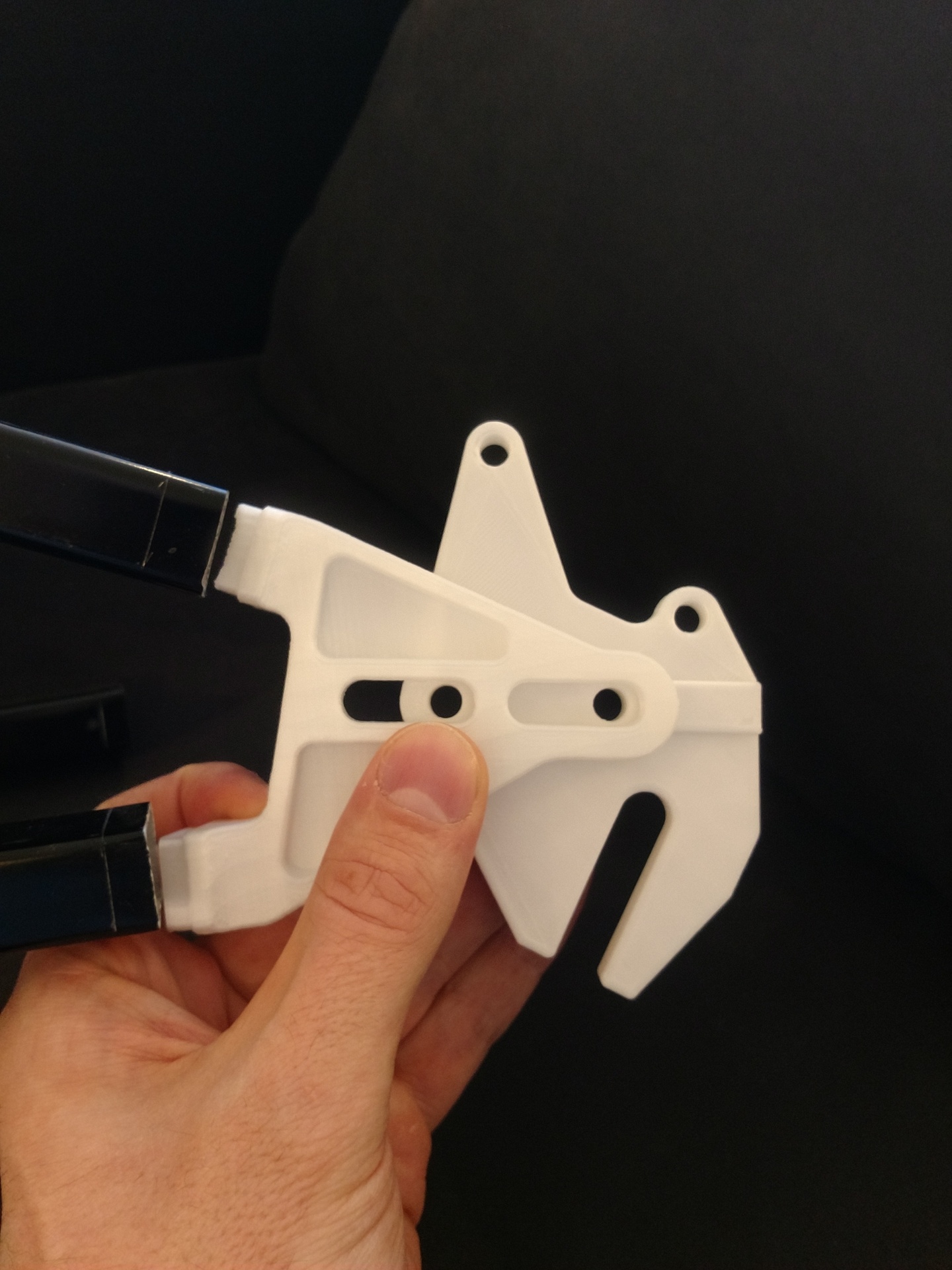

At some point in the period I was thinking about this (it was a low priority project over a year or two), I finally got myself a 3D printer, and of course I put it to work printing prototypes.

Ultimately what put an end to the project though is that I killed the frame by landing a jump badly, bending the (insubstantial it has to be said) shock mount, and cracking the frame around the welds.

Oh well. It wasn’t really the right kind of bike for the sort of riding I was doing anyway.