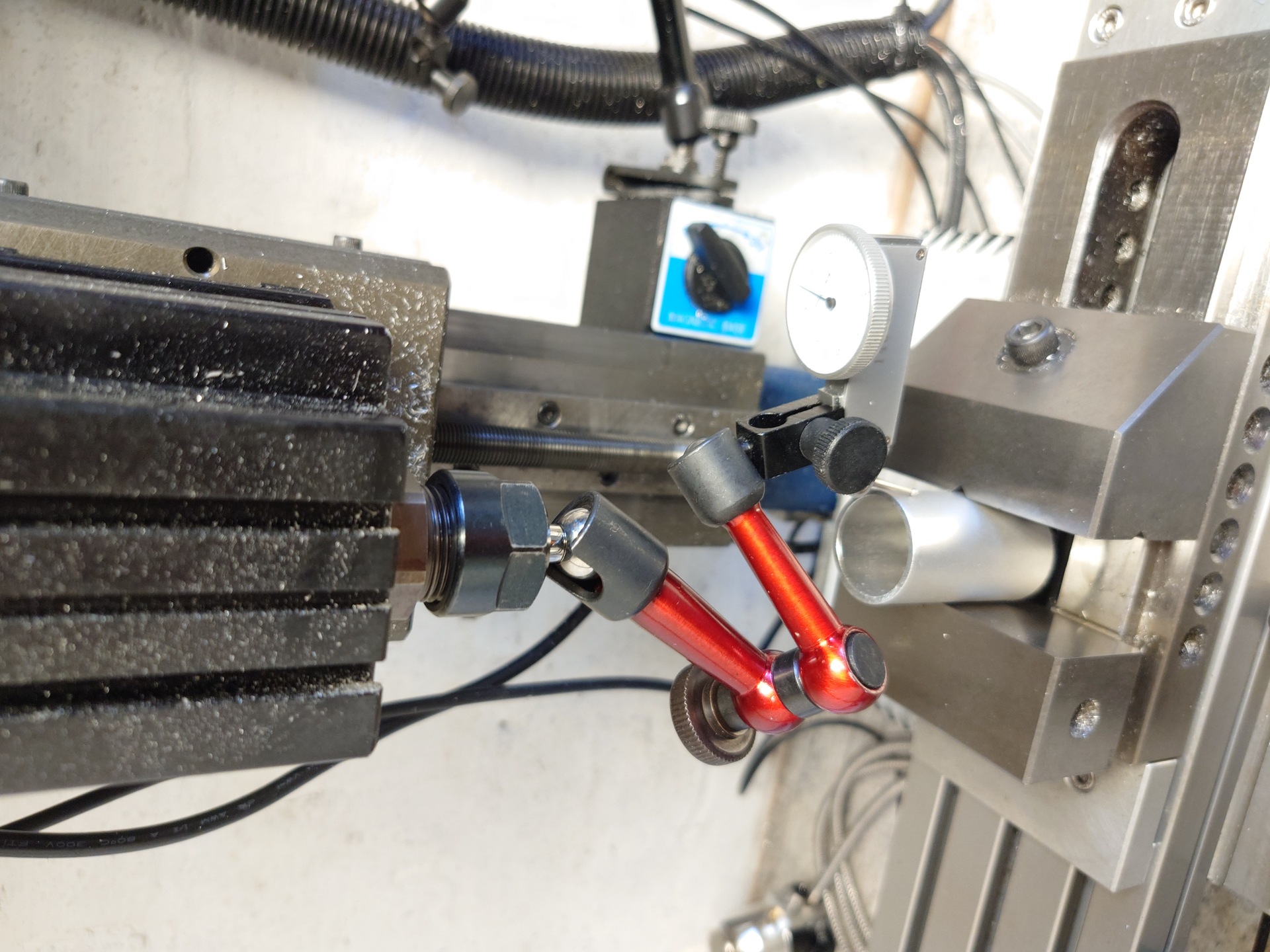

Sometimes when CNC machining it makes sense for the program zero to be directly on some existing circular feature. To measure this position you need to be able to hold a dial test indicator concentric with the spindle, using some kind of holder.

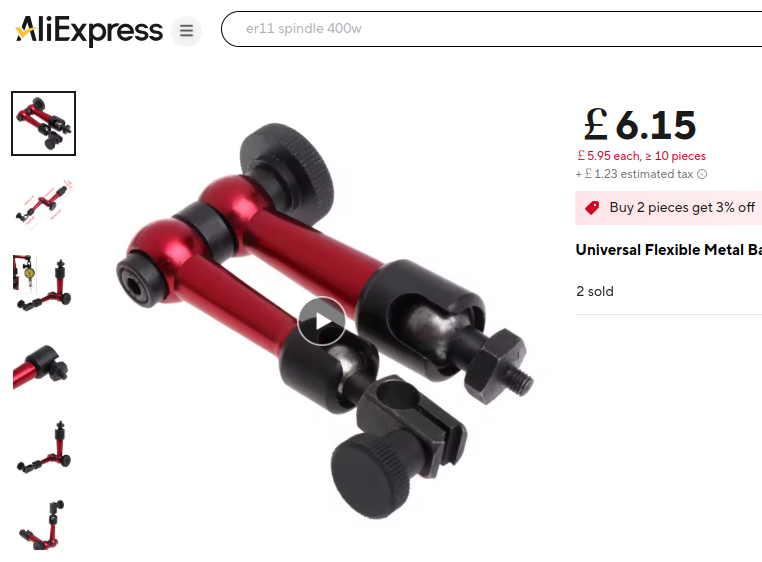

Can we pause for just a second and marvel at how absolutely bonkers it is that something like this can be designed, manufactured and shipped halfway around the world, and still presumably make the seller a profit? Anyway, as you can see this is designed to screw into some fixed point, as opposed to being held in a spindle. You could probably get away with grabbing the stubby thread in a collet, but it’s hardly ideal. What could I do instead?

Wait what?

Oh.