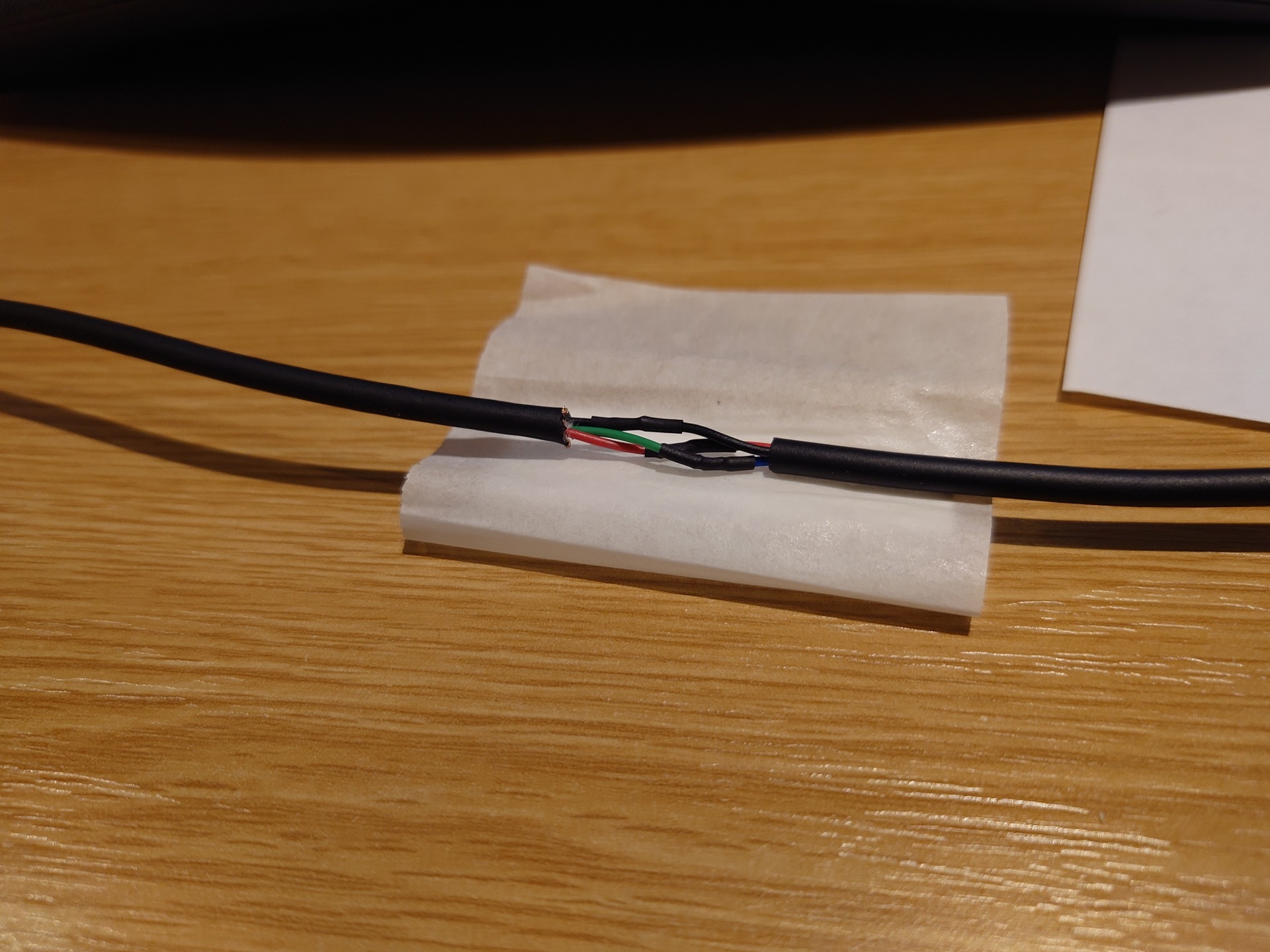

For reasons, I needed to extend a cable, which meant splicing a section into the middle of it. This cable was going to be used outdoors, so it needed to be moderately water proof.

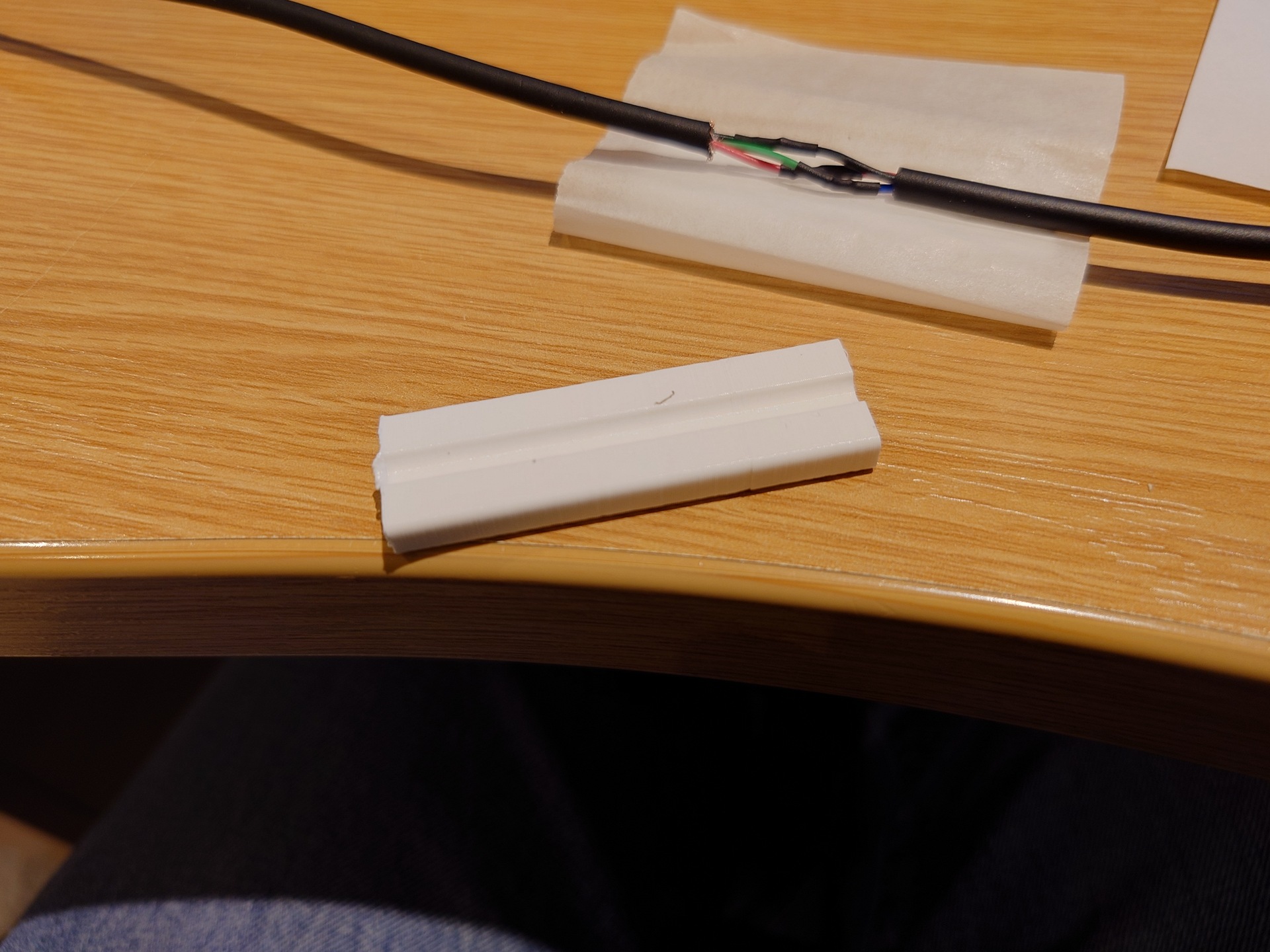

I 3D printed a couple of moulds, roughly the dimensions of the cable outer.

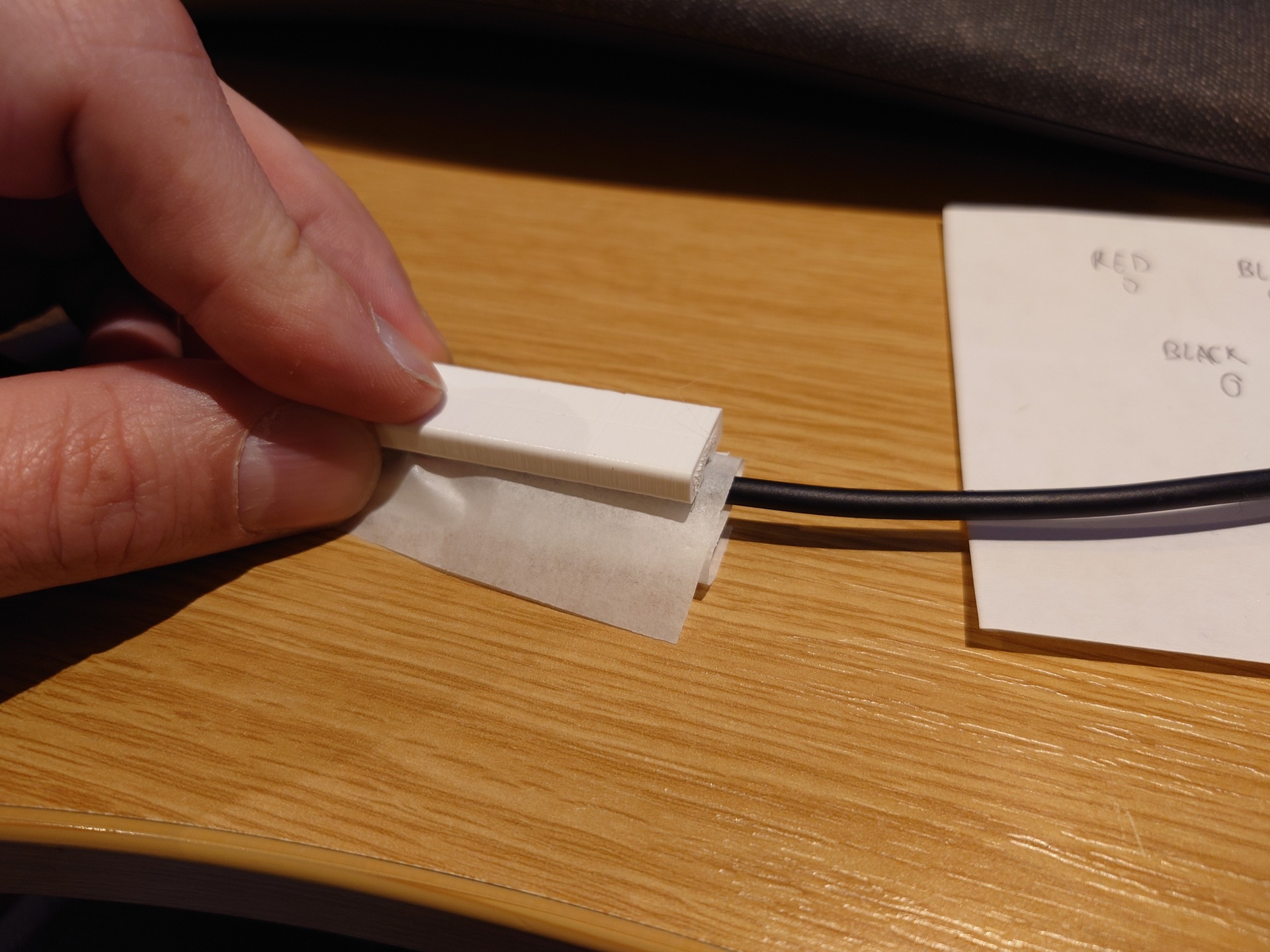

Then I used a glue gun to liberally coat the “naked” portion of the join from all angles, wrapped it in grease proof paper, quickly pressing it between the two moulds.

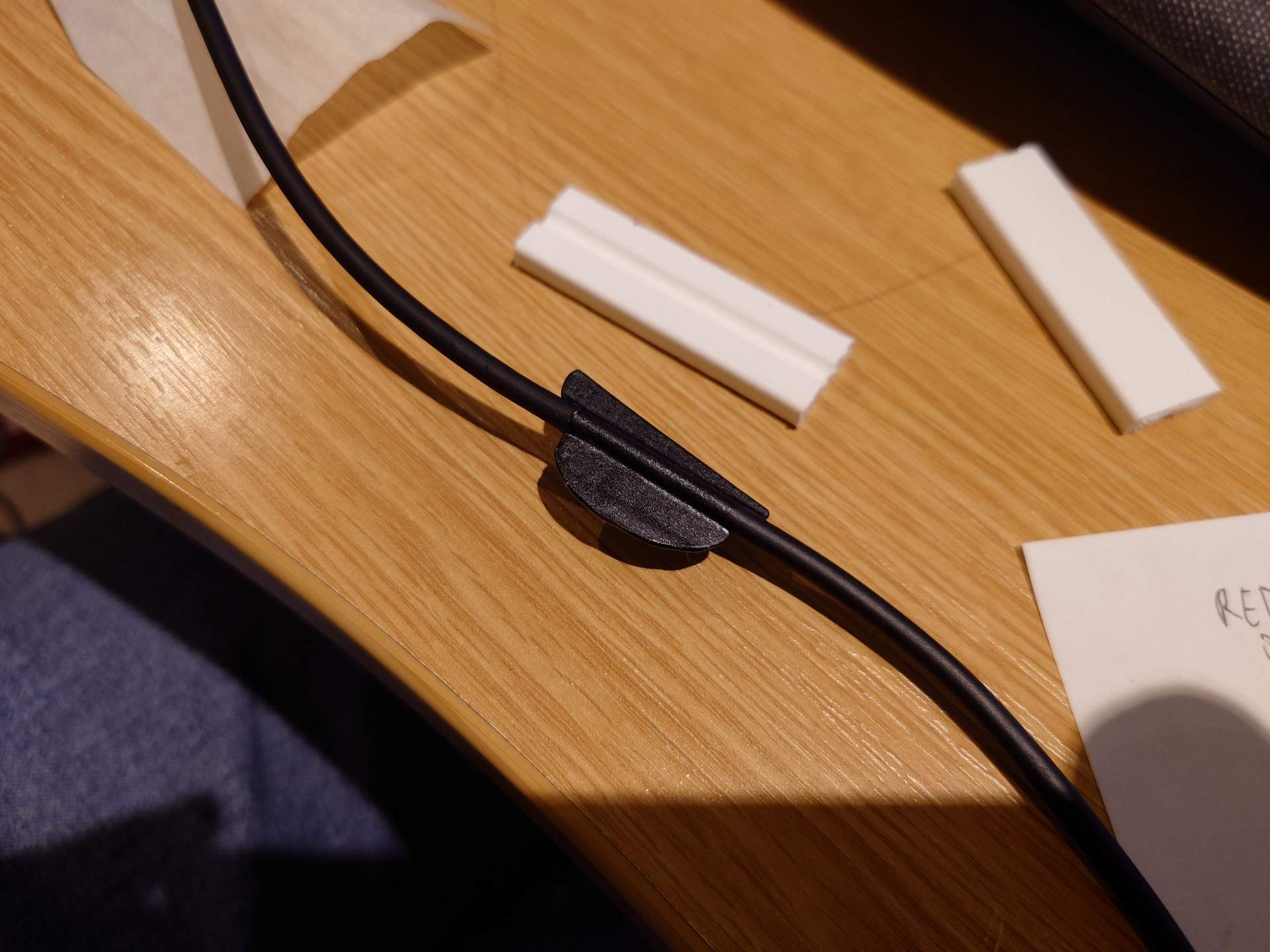

The excess was trimmed, and I then applied a bit of external heat shrink as a belt and braces measure.

It’s probably churlish to claim to have invented this idea, but I did at least come up with it independently. I’m fairly sceptical it will last in the long term, as in my experience glue gun glue has a tendency to get brittle over time. It doesn’t have to work for long anyway, as I have the correct longer cable to swap out at a later date, but I thought it was an interesting technique that was worth sharing.